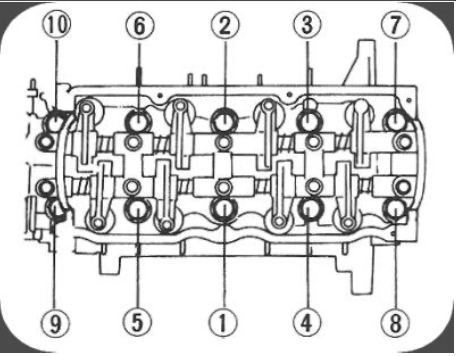

Above is the torque sequence for the B2200 cylinder head. Torque should be done in 20 lb/ft. steps until final torque. Torque numbers are below start with bolt one.

Bolts 1-10: 59-64 ft/lbs.

Re-torque bolts at 64 ft/lbs after the engine has gone through a few heat cycles.

Bolt and block threads should always be cleaned before installation. Use a chaser tap or an old head bolt to thread into the holes in the block to clean them before assembly. Never use a cutting tap to clean bolt hole threads. Bolts should never be installed dry, always coat the bolt threads with engine oil, ATF, or high pressure engine assembly lube before installing, the thicker the better. The gasket surface of the head must be perfectly clean and as close to mirror finish as possible.

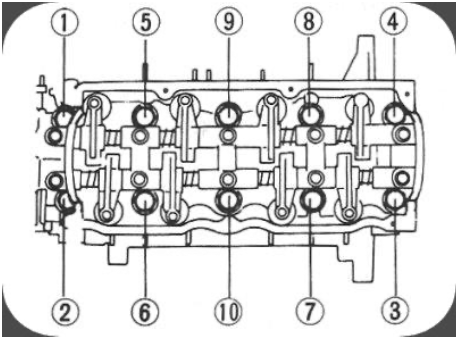

The Removal Sequence

Bolts should be un-torqued in the sequence above in 2 or 3 steps or 1/8th turn on the first step, another 1/4 turn on the second step and then completely loosen.

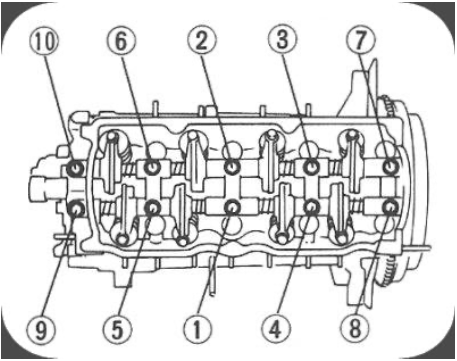

Rocker Assembly Torque Sequence

Bolts should be lightly hand tightened in sequence first, then torqued to spec.

Bolts 1-10: 13-20 lb/ft.

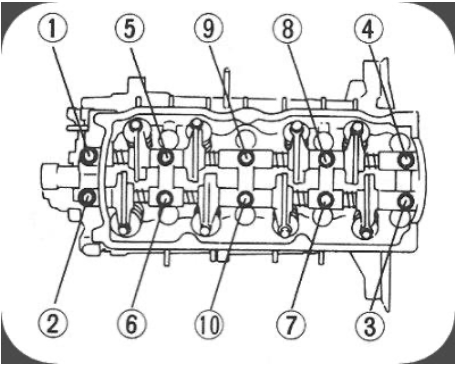

Rocker Assembly Removal Sequence

Bolts should be loosened 1/4 turn in sequence then completely loosened.

Common Problems

Engine overheating can be caused from the timing belt or distributor being installed wrong causing the ignition timing to be advanced. Checking your timing and correcting anything that isn’t aligned properly may fix the problem. A good indicator of incorrect timing is the distributor needing to be slid all the way forward or backwards for the truck to run.

A second common reason for engine overheating within a year of replacing a head gasket is failure to re-torque the head. Re-torqueing the head must be done because of thermal expansion. When the engine gets up to full operating temperature the cylinder head expands and causes the head gasket to compress more than it would while the engine is cold. This causes the head gasket to permanently compress a certain amount which releases tension on the head bolts. To ensure this does not happen the head bolts must be re-torqued after the engine has gone through a few heat cycles. A heat cycle is when the engine is operated up to full operating temperature and then allowed to cool down to ambient outside temperature. After you have run the engine a few times and allowed it to cool remove the valve cover and set your torque wrench to the maximum head bolt torque listed above, then tighten each bolt in sequence. Never loosen a head bolt after the head gasket has been installed, doing so may cause the head gasket to blow.

Oil in the water, coolant loss, or rapid coolant system pressure can also be caused from not re-torqueing the head after installation. Oil in the water is more common if residue is left on the cylinder head or block surface during installation, ALL chemical and old head gasket residue must be removed when installing a head gasket. If the coolant system pressurizes quickly (in the first 1-3 minutes of operation) it is usually accompanied by overheating or an abnormally high operating temperature.

Additional Notes: Cylinder heads should always be checked for warpage when they are removed or before installing a new head. Less than .003″ warpage is acceptable anything more than .003″-.005″ warpage and the head should be straightened then shaved. All overhead cam design heads need to be straightened before shaving otherwise the cam towers will be out of alignment and you run a high risk of burning up the camshaft. When looking for a machine shop choose one that is racing oriented or a speed shop, these shops should have better equipment, more knowledge, and will care more for getting the job done right.

After you finish installing the head and double check everything, fire up the engine, and let it warm up. Once warmed up (at least 1/4 on temp gauge) turn off the truck and allow to fully cool. Remove valve cover and re-torque the head using your final torque setting in sequence. Not doing this may cause premature head gasket failure within a few months to a year.

Leave a Reply