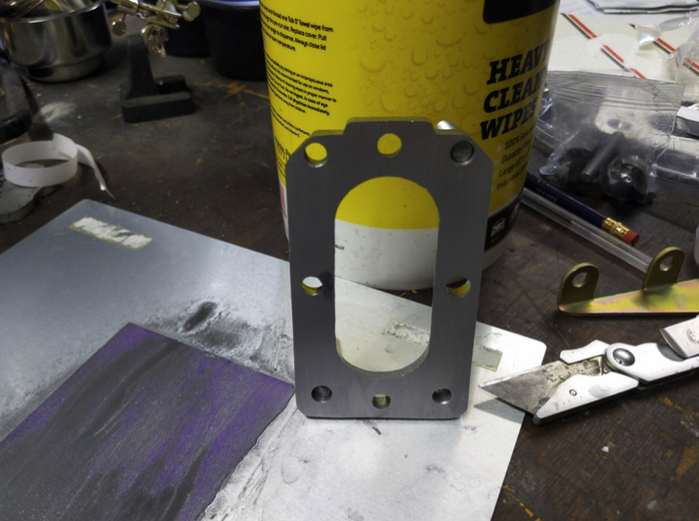

Sanding Weber adapter plates flat helps to seal everything up and prevent vacuum leaks.

Lets begin!

Get a flat surface, I have a piece of aluminum, or you can use some glass, just something good and flat.

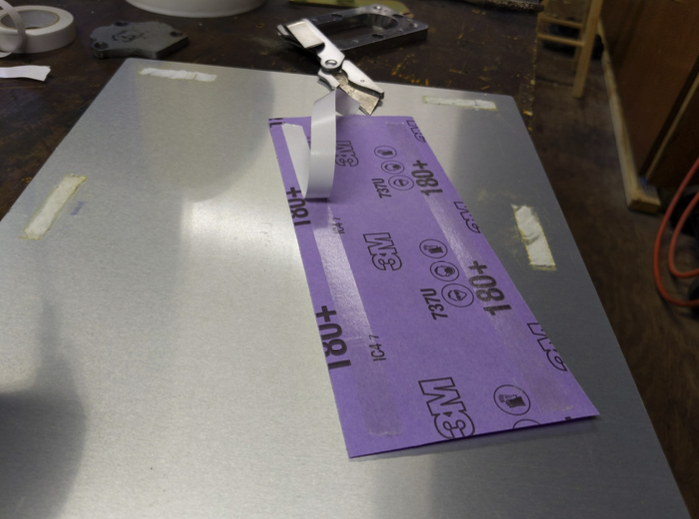

Attach 180 grit sandpaper to a flat surface. I used double-sided tape and stuck the sanding paper to my sheet of flat aluminum.

I used WD-40 for lubricity. I held each piece by hand and moved it across the sandpaper in a back and forth motion. I would check every so often and I could see the high and low spots during the sanding action. I knew I was don’t when I realized it was all flat and looked like a nice machined surface.

Gather Supplies. WD-40, 180 Grit automotive sandpaper, spray glue or thin double-sided tape to hold the paper down to your flat surface. A flat surface such as a sheet of glass or metal. You may also want to use gloves as this will get your hands coated in aluminum.

Stick the sandpaper to the flat surface using double-sided tape or spray glue.

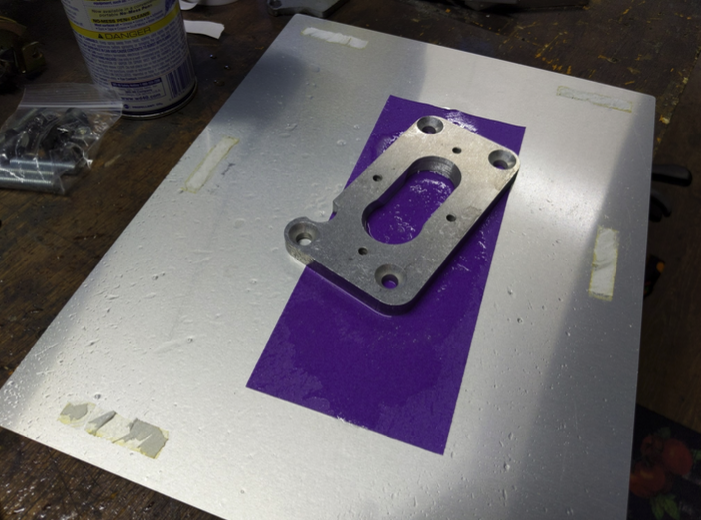

Spray the work surface with WD-40 to help prevent the sandpaper from gumming up. Start sanding back and forth.

After only a few strokes I can already see some high and low spots.

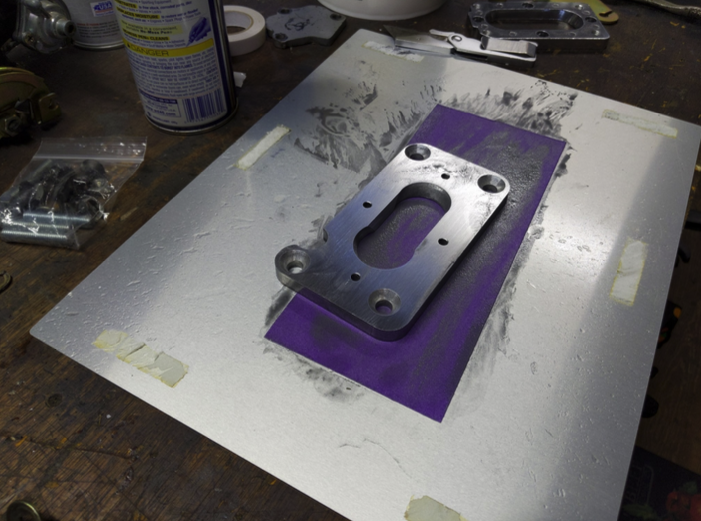

I sanded BOTH sides of this adapter plate.

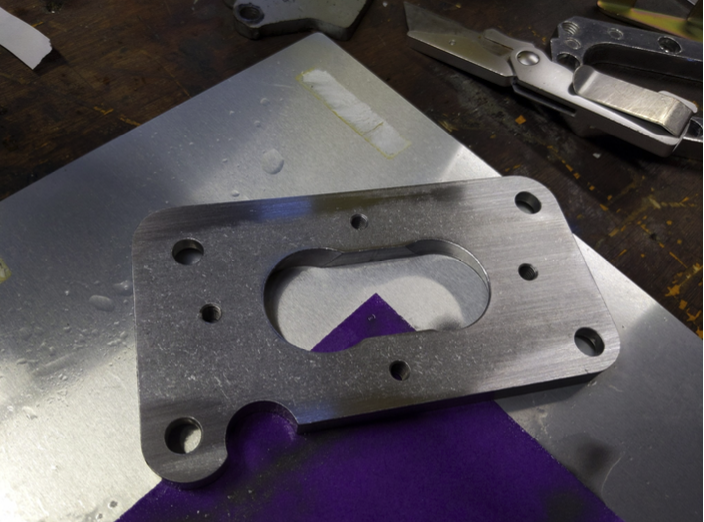

This is the “top” plate and it is usually the worst one. Look at the highs and lows revealed on this one!

Now its slick just like a perfectly machined surface.

All nice and perfectly flat.

You are pretty much done at this point. You can use the gaskets that came in the kit and using a pencil, trace them onto FELPRO material that you can usually get at any Auto Parts Store. Cut the new gaskets out and this material will last a lot longer than what comes with the carb kit.

The best sealer to use is Permatex Aviation as its fuel resistant and nice and sticky. Never use plain RTV as gasoline will disintegrate it.

Use this:

BONUS INFO:

Using a Dremel or hand file, remove the excess material on the adapter plate that will be in the way where your PCV hose will connect to your intake. If you do not do this now, you will have a hard time getting your hose on later.

See how this opens it up more?

CAUTION

Be really careful how you tighten the plates during installation.

No one has any specific torque specs. You will just have to know when tight is tight and not over tighten the top plate as it will CRACK and you will have a leak you can’t easily find.

You can watch me do this in this video where I install a Weber Carburetor on a friends truck.

Leave a Reply