So you may have a ticking sound coming from your engine, and through the interwebs you may have read that its the hydraulic lifters or that the valves need adjusting.

Then you ask yourself…

- I am new to these trucks, what is a valve train?

- How can you tell which valve train I have?

- How do I adjust the valves?

- What are the pros and cons to changing out the valve train from hydraulic to mechanical or vice versa?

I need to preface by saying my website and my YouTube channel focus primarily on the 86-93 models, but lets take it back a little bit and discuss the 3rd and 4th generation of Mazda B2000, B2200, and B2600 Pickups.

The 3rd generation of these trucks were made from 1977-1985. These trucks came with a 1.6, 1.8, or 2.0 configuration, and sometimes a 2.2 liter diesel. All of these had a mechanical valve train with adjustable rockers arms.

The 4th generation (1985-1998) came with the 2.0, 2.2, 2.6 and 2.5 in Thailand. In the North America markets this generation only ran from 1985-1993. After 1987 most were equipped with non adjustable hydraulic lifters in the valvetrain.

So what is a valvetrain?

A valvetrain is a mechanical system that controls the operation of the intake and exhaust valves in an internal combustion engine. These Mazda trucks came with two configurations in the valvetrain, the mechanical lifter setup and the hydraulic lifter setup.

The mechanical lifters were adjustable. As per the owners manual, they require adjustment every 15,000 miles. When they were out of adjustment, you would often here a ticking or tapping sound from the top of the engine.

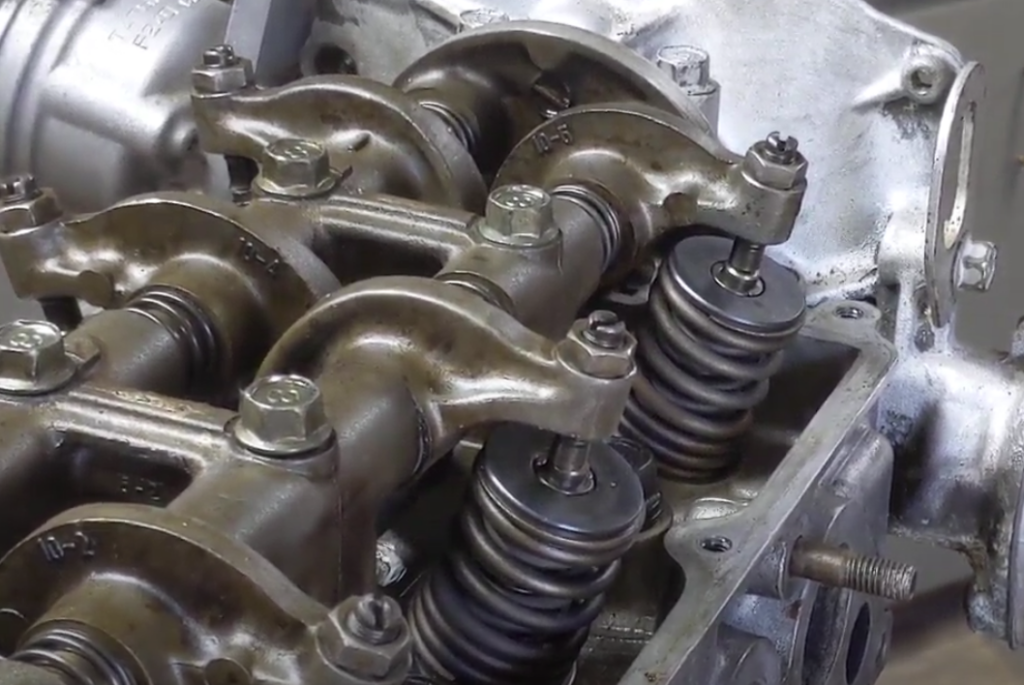

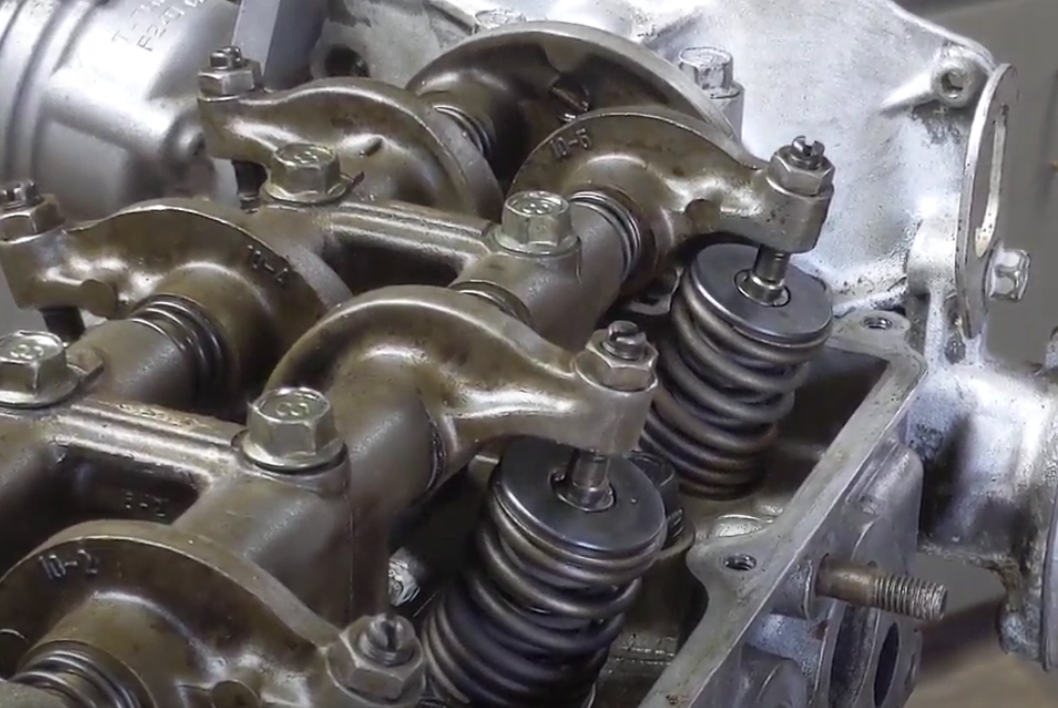

This is a mechanical valvetrain setup. This is adjustable.

Set to .008 warm/hot or Set to .010 cold

The hydraulic lifters were a non adjustable setup and required no maintenance.

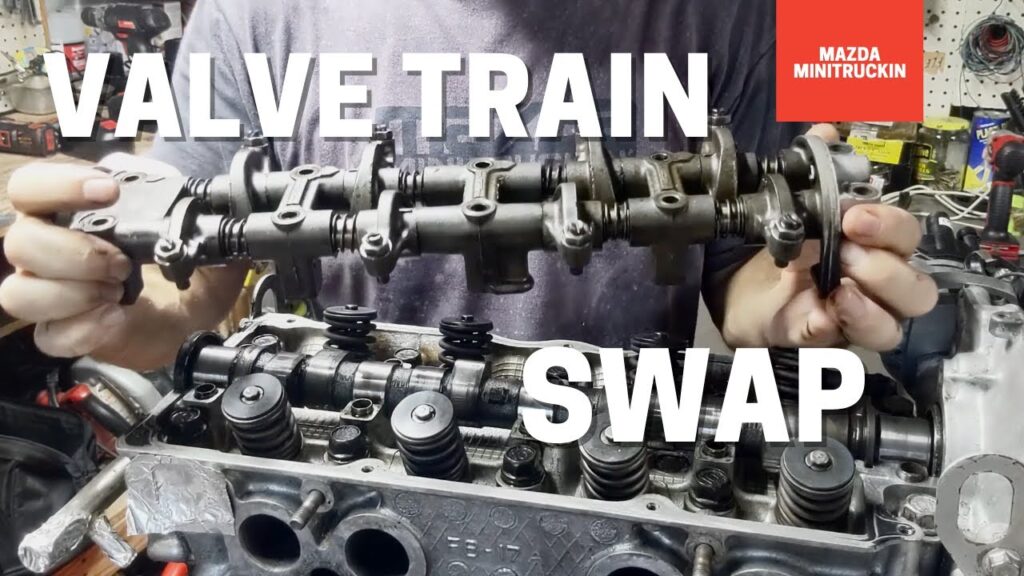

This is a hydraulic lifter valvetrain setup. These are non adjustable and seen on the 2.2 and 2.6 engines.

This is a 2.2 engine.

This is a 2.6 engine.

If you have a 1986-1987 2.0, the odds are extremely high that you have a mechanical valvetrain that is adjustable and requires adjustment every 15,000 miles per owners manual.

If you have a 1988-1993 2.2 or 2.6 liter engine, its highly likely you have the hydraulic lifters that are non adjustable.

To find out which setup you have, you can easily take your valve cover off and inspect the valvetrain to see what you have. That is actually the best thing to do. You cant simply trust the the timing covers says 2.0 or 2.2 and gamble on which valvetrain setup is in there. These days a lot of these trucks have been through several owners and some have swapped later models that had the hydraulic setup for the mechanical setup.

Some have swapped the valvetrain alone, but many just swap or buy a new complete head. Any cylinder head that you buy today will come with the mechanical setup. A lot of us call these cylinder heads with the mechanical setup a 2.0 head.

If you swap the valvetrain alone, you MUST use the 2.0 cam with the mechanical setup. Despite what some say, the 2.2 cam is different and if you use the 2.2 cam with the mechanical setup, and adjust your rockers, you WILL NOT get all the tapping noise out. This will make you want to adjust a tighter tolerance and you will most likely wipe your cam out.

- 2.0 cam = mechanical lifter setup

- 2.2 cam = hydraulic lifter setup

Want to know how to adjust the rockers/valves?

WATCH THIS VIDEO

Can you put a 2.0 head on a 2.2 block?

You most certainly you can. The heads are the same. The only thing that you really want to pay attention to, is the head gasket. The head gasket MUST match the block you are using. So that means if you are using a 2.0 block, use the 2.0 head gasket. If you are using the 2.2 block, use the 2.2 head gasket. This is due to an oil restrictor in the block. The 2.0 does not have one and is included in the head gasket for the 2.0. the 2.2 has on pressed into the block, so the 2.2 head gasket doesn’t have the restrictor built in.

Why would anyone swap the valvetrain from the non adjustable maintenance free to a mechanical setup that you have to adjust every 15,000 miles?

To answer that, we must first understand where and why the ticking starts.

Lets face it these trucks are old, and some truck owners have gotten their trucks on marketplace or what have you and the engines were neglected as far as oil changes go. Neglect in oil changes can cause a build up of sludge. With each new oil change the detergents in the oil can break up some of the sludge and the debris can fall into and get trapped in the tiny orifices of the hydraulic lifters causing them to lose prime and thus will collapse and start tapping.

Many have followed my videos and replaced the hydraulic lifters with great success. A few have not. For those few, the reason is usually that the engine has so much gunk in them, that the new lifters get stopped up.

This is why almost all cylinder heads sold today are of the mechanical configuration. Its just easier on the seller or manufacturer, and once you adjust the rockers, its pretty much guaranteed to work and not be noisy.

Want to see how to swap the valvetrain?

WATCH THIS VIDEO

So what are the pros and cons to changing out the valve train from hydraulic to mechanical or vice versa?

Hydraulic setup:

The pros to this setup are its maintenance free if you do timely oil changes and use a good oil.

The cons to this setup is that over time the lifters may get weak or the tiny oil holes will get stopped up with sludge and cause them to collapse and start to tap.

Mechanical Setup:

The pros are that you will never really have to worry about the lifters getting stopped up and start to tap/tick. Some have said this setup gives the engine a tad more horsepower.

The cons to this setup are that you have to adjust them periodically, but its really good for you to know how to do this in my opinion.

Hope this has helped answer a few questions on the subject matter.

If you like this content, and want to see more, don’t forget to subscribe to the newsletter, and while you are visiting my YouTube channel, subscribe to that as well.

Subscribe to our newsletter!

Comments

One response to “Mechanical vs Hydraulic ValveTrain”

Recomandations on where i can buy a complete mechanical head for a 1993 2.2?